Connector Care: The Hidden Key to RF Accuracy and Equipment Longevity

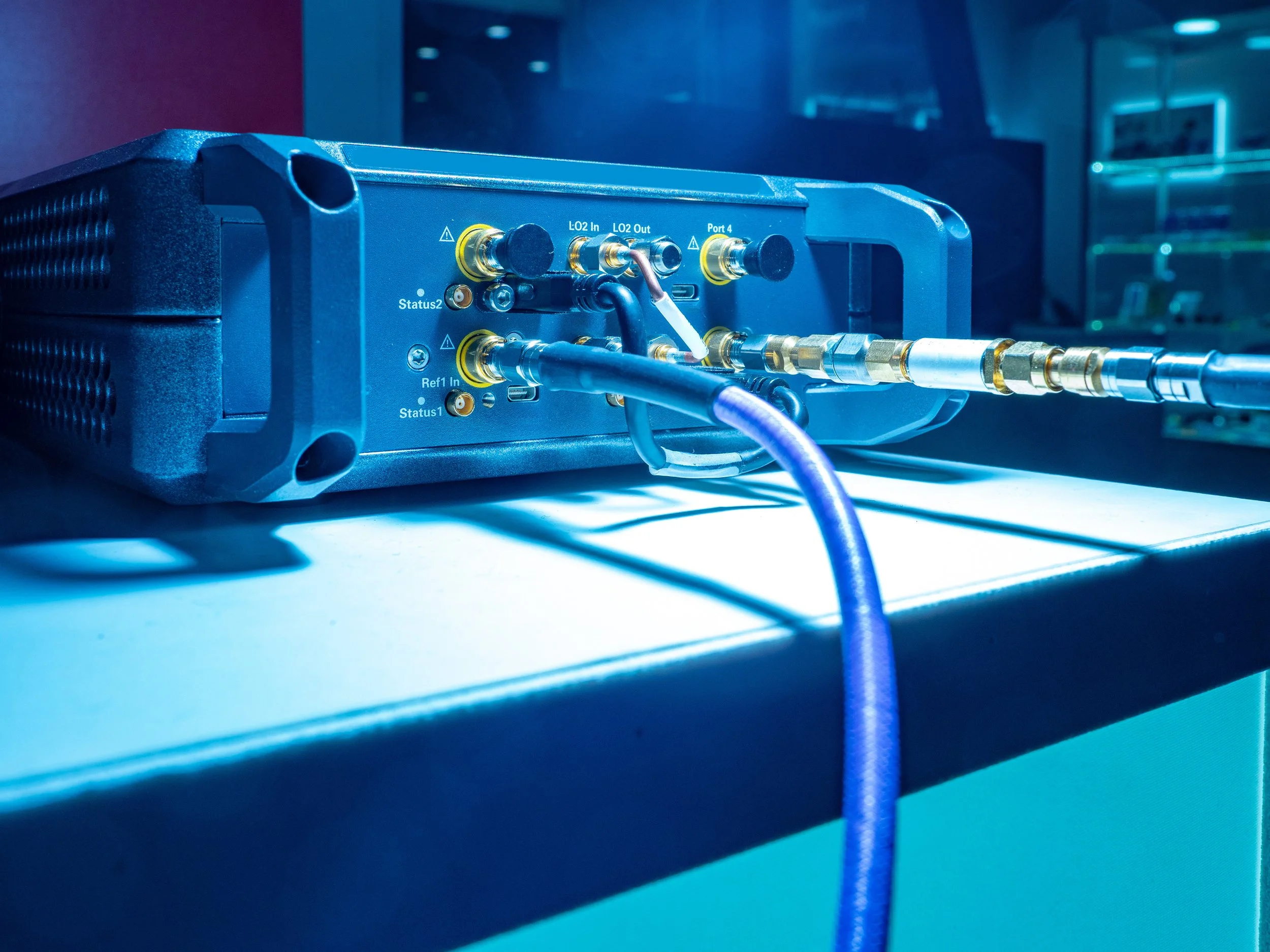

In high-frequency environments—RF manufacturing, aerospace, defense, and telecom—tiny details can cause big problems. One of the most common sources of inaccurate readings and unplanned downtime is also the most overlooked: connector care. At Tra-Cal, we routinely receive RF instruments that customers believe have failed. After inspection, we find the root cause is improper connectors—not the instrument.

Why Connector Care Matters

Connectors are the bridge between your instrument and the device under test. Any contamination, dimensional mismatch, or mechanical damage can alter impedance and return loss, driving measurement errors and damaging expensive front-end ports. Poor connector care often results in inaccurate measurements, equipment damage, and costly repairs or downtime.

1. Keep RF Connectors Clean

Even microscopic debris can skew readings at microwave and mmWave frequencies. Use lint-free swabs and high-purity isopropyl alcohol, allow full evaporation, and blow away particulates with clean, dry air. Never touch mating faces with fingers, and always cap unused connectors with clean dust caps.

2. Understand RF Calibration Duration & Standards

Precision RF connectors are not interchangeable. Forcing a 2.92 mm into a 3.5 mm, or using the wrong adapter gender or polarity, can permanently damage both sides. Always verify the type and size (SMA, 3.5 mm, 2.92 mm/K, 2.4 mm, 1.85 mm, N-type, etc.), match frequency rating and power handling, and use metrology-grade adapters to protect instrument ports.

3. Apply the Proper Connector Torque

Torque is a specification—not a feel. Under-torque can cause intermittent contact and variable S-parameters; over-torque deforms the interface and degrades return loss. Use a calibrated RF torque wrench and follow OEM specifications (e.g., many SMA connectors require approximately 8 in-lbs). Re-calibrate torque tools regularly to maintain accuracy.

4. The Real Cost of Neglect

Improper connector care leads to out-of-tolerance measurements, scrapped work, schedule slips, and port repairs that can cost thousands of dollars. For mission-critical programs in aerospace and defense, a single connector incident can bottleneck qualification and acceptance testing.

5. Training and Continuous Reinforcement

Connector handling is a practical skill. At Tra-Cal, we embed connector care into technician onboarding and revisit it frequently—just as we recommend to our customers. Make it part of your culture: hold quarterly refresher training with hands-on demos, use standardized connector inspection checklists, and include torque verification as part of setup and teardown.

A Tra-Cal Perspective

We often find customers’ RF instruments are perfectly fine—the problem was improper connectors or torque. After cleaning, confirming the correct size and type, and torquing to specification, performance returns to normal. That’s why connector care is a core step in our ISO 17025 processes for RF manufacturers, telecom providers, aerospace primes, and defense contractors.

Key Takeaways for RF Teams

• Clean every time. Cap every time.

• Verify connector type, size, and gender before mating.

• Always use a calibrated RF torque wrench.

• Make connector care a recurring training topic.

At Tra-Cal, we provide ISO/IEC 17025-accredited calibration and connector inspection for VNAs, spectrum analyzers, power meters, and more. Proper connector care ensures accurate results, reduces downtime, and protects your investment.